Garnet sand selection & Production cost

Garnet Abrasives: Market Dynamics Driven by Demand and Cost Due to its core advantages of low dust and recyclability, garnet abrasives have seen a continued increase in sandblasting, water treatment and other fields in recent years.

Why Glass Beads Surface-Friendly Than Other Abrasives?

Glass beads exhibit greater surface-friendliness compared to numerous other abrasives, such as alumina, silicon carbide, and steel grit. This characteristic is primarily attributed to its distinct physical and chemical properties. The surface-friendliness of glass beads is manifested in the ability to clean or polish surfaces efficiently while minimizing damage to the work piece itself.

Different standard of the surface cleanness technology

Surface cleanness is very important for the work pieces or metal parts before coating and painting . Usually, there is no single, universal cleanliness standard and it depends on the application. However, there are indeed some general guidelines include visual cleanliness (no visible dirt, dust, or debris) and adherence to industry-specific standards like ISO 8501-1 for industrial cleaning or NHS

Dry sandblasting vs Wet sandblasting vs Vacuum sandblasting

The operation speed is slow. It is not suitable for processing large workpieces and the equipment cost is relatively high.

The Ultimate Revelation of the Effects of Non-metallic Abrasives in Different Sandblasting Scenarios

Non-metallic abrasives are widely used in various sandblasting scenarios, with significant differences in effects. The key considerations for choosing non-metallic abrasives are as follows:

Application of traditional sandblasting abrasives in the new energy industry

As we all know, traditional sandblasting abrasives have a wide range of applications across various industries. Today, we will focus on their applications in the New Energy Industry.

Application of Abrasives in Automobile Manufacturing: Selection and Quality Improvement

In the field of automobile manufacturing, the rational selection of blasting abrasives plays a crucial role in improving the surface treatment quality of automobile parts. Different types of abrasives have their own unique properties and are suitable for different stages of automobile manufacturing.

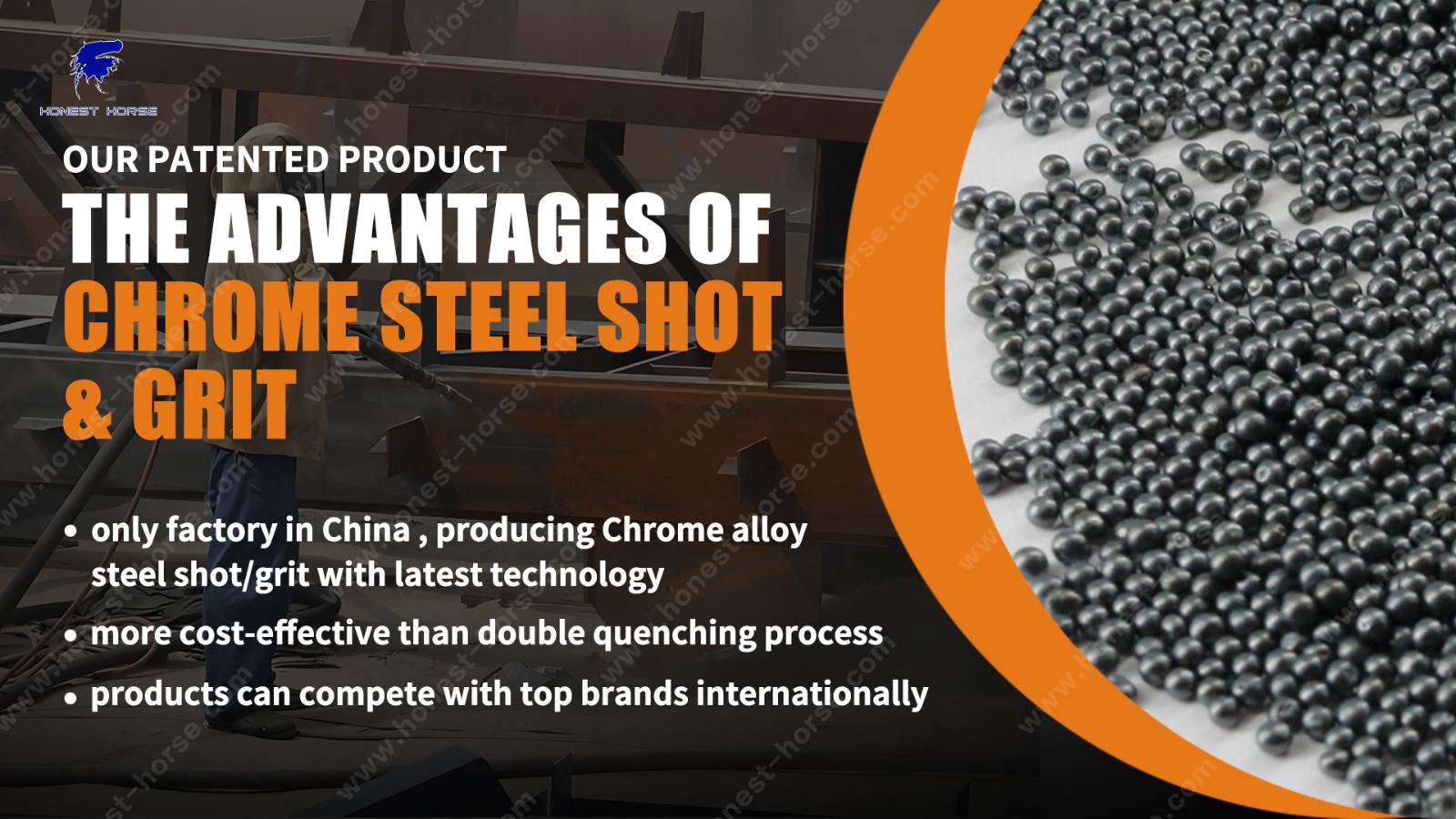

The Advantages of Chrome Steel Shot &Grit-Our Patented Product

We,Jinan Junda Industrial Technology Co.Ltd,produce two types of steel shots&grit. Standard Steel Shot/Grit & Chrome Steel Shot/Grit. The Chrome Type contains Cr element 0.2-0.4% has longer fatigue life, reaching up to 2600-2800 times.

How Can Enterprises Optimize Procurement and Usage Strategies?

In recent years, the continuous price increase of abrasive blasting media has imposed significant cost pressures on industries such as manufacturing, ship repair, and steel structure treatment. To address this challenge, enterprises must optimize both procurement and usage strategies to reduce costs and improve efficiency.

Guide to the best abrasive selection

In shipbuilding and large steel structure anti-corrosion projects, the selection of abrasives needs to be combined with factors such as rust removal efficiency, surface quality, environmental protection and cost. The advantages and applicable scenarios of different abrasives are significantly different, as follows:

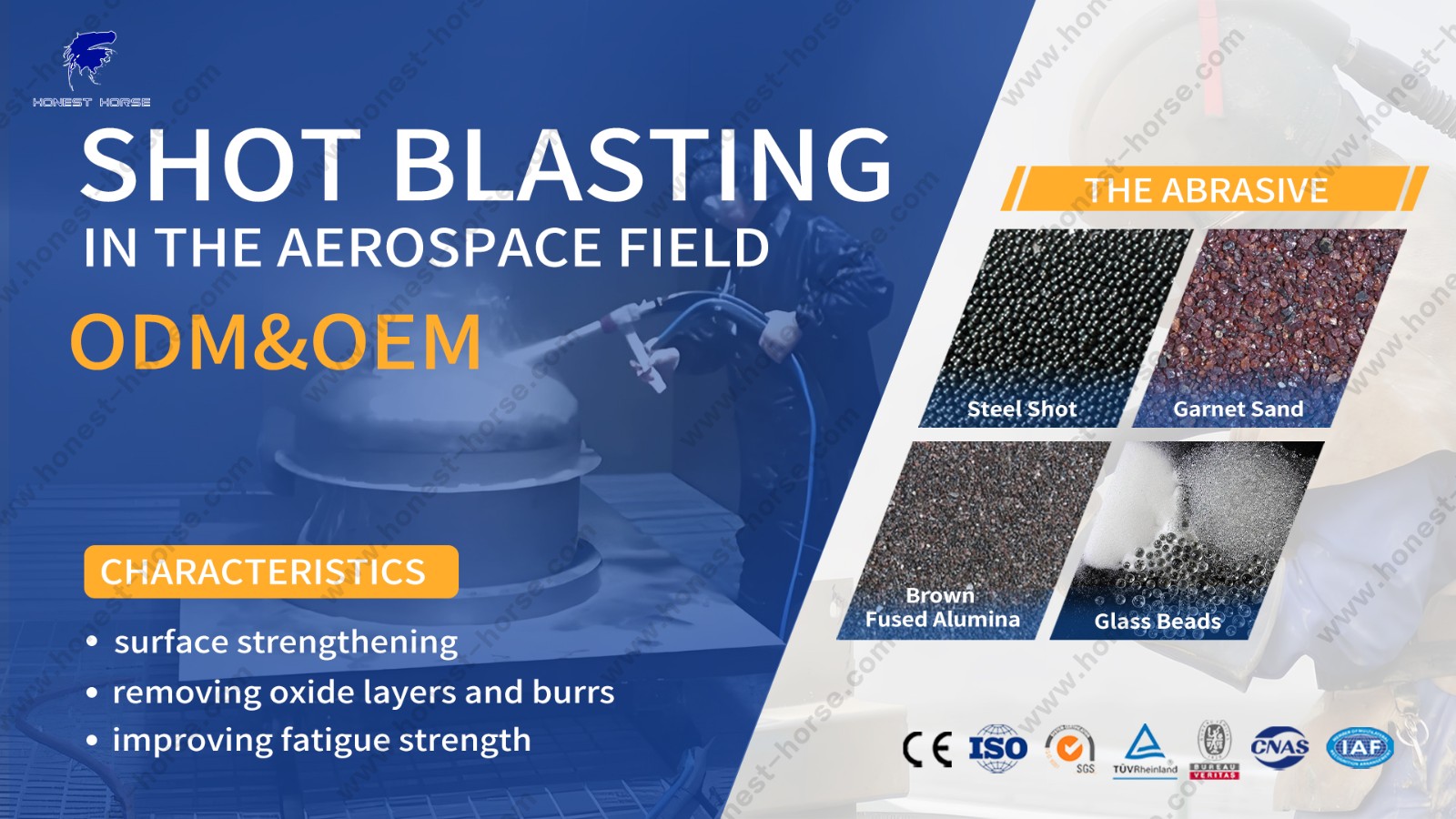

Characteristics and requirements of shot blasting

Shot blasting in the aerospace field has the characteristics of surface strengthening, removing oxide layers and burrs, and improving fatigue strength, and has strict requirements on shot type, processing parameters, surface quality, etc.

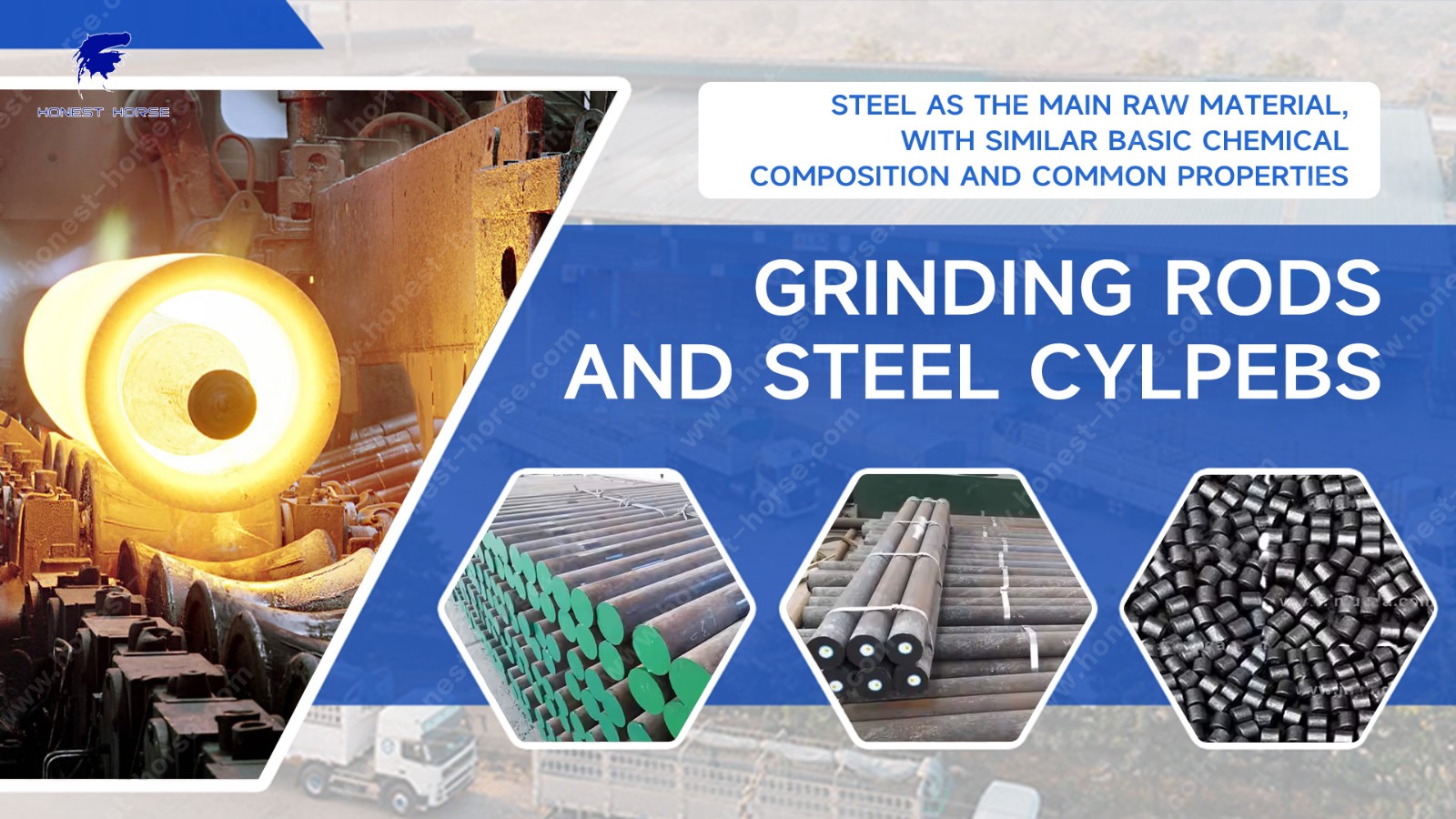

Grinding Rods and Steel Cylpebs

Characteristics and Applications of Grinding rods and Steel Cylpebs Grinding rods are formed by pressure and have a well-aligned grain structure that can better withstand warping and wear. It is a com

Happy Mid-Autumn Festival!

Harvest moon high, spirits higher. Hones-horse celebrates unity and tradition this Mid-Autumn Festival. Savor our mooncakes, symbolizing our commitment to quality and togetherness. Let lanterns light

2005-2022 © All Rights Reserved.HONEST HORSE (CHINA) HOLDING LIMITED

English

English Spanish

Spanish Arabic

Arabic