Why Glass Beads Surface-Friendly Than Other Abrasives?

The following are several key factors contributing to this phenomenon:

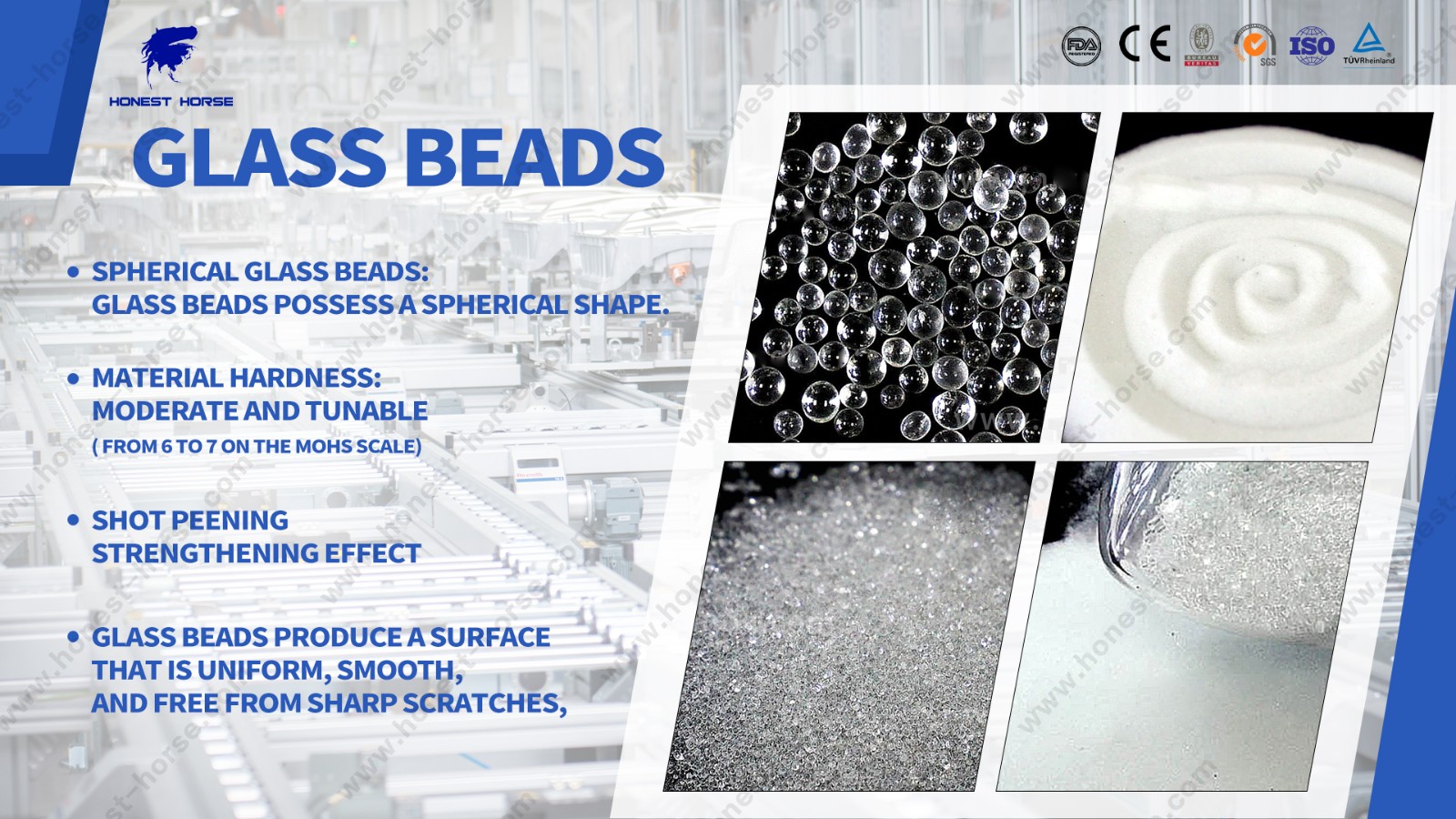

1. Shape and Structure: Spherical vs. Angular

- Spherical Glass Beads: Glass beads possess a spherical shape. During the sandblasting process on workpiece surfaces, they establish point contacts. This contact mode results in relatively low stress concentration. The action is more akin to a "tapping" or "rolling" effect, mainly serving to remove fragile surface contaminants, such as rust layers and old paint films, without deeply penetrating into the workpiece material.

- Angular Abrasives: In contrast, abrasives like brown corundum, steel grit, and copper slag typically feature sharp and irregular edges. When used for sandblasting, they make line or point contacts, generating substantial local stress. This is analogous to numerous tiny chisels carving the surface.

The spherical shape of glass beads effectively avoids the cutting and pitting caused by sharp edges, thereby significantly reducing workpiece wear and minimizing the increase in surface roughness.

2. Material Hardness: Moderate and Tunable

The hardness of glass beads generally ranges from 6 to 7 on the Mohs scale. This hardness level is sufficient to effectively remove common surface contaminants, such as rust (with a Mohs hardness of 4 - 5) and old paint films. Simultaneously, it is either lower than or comparable to the hardness of many metal materials.

3. Shot Peening Strengthening Effect

The spherical impact of glass beads on metal surfaces generates a uniform and minute compressive stress layer. This layer confers several benefits:

- Enhanced Fatigue Resistance: It improves the fatigue strength of metal components, effectively resisting the initiation and propagation of cracks.

- Reduced Stress Corrosion Risk: The compressive stress layer decreases the likelihood of stress corrosion.

- Improved Wear Resistance: By inducing slight cold work hardening on the surface, it enhances the wear resistance of the material.

4. Surface Finish

Due to their spherical shape and impact characteristics, glass beads produce a surface that is uniform, smooth, and free from sharp scratches, often referred to as a "satin finish". This finish provides an ideal substrate for subsequent spraying, coating, or electroplating processes, ensuring strong coating adhesion.

Conversely, angular abrasives create a rough surface topography with peaks and valleys. While this can also enhance adhesion to some extent, it consumes more coating material and results in a less aesthetically pleasing surface appearance.

In light of these advantages, glass beads are frequently employed in applications where the integrity of the substrate is of utmost importance, such as the processing of precision parts, molds, aerospace components, stainless steel products, and aluminum alloy die-castings. They represent an optimal choice for achieving a balance between effective surface cleaning and substrate protection.

2005-2022 © All Rights Reserved.HONEST HORSE (CHINA) HOLDING LIMITED

English

English Spanish

Spanish Arabic

Arabic