Features

1. Uniform composition, pure particle size, moderate hardness and long life.

2. It can not only remove large burrs without abrading the surface of the

product, but also form an anti-corrosion

ayer on the metal surface.3 Unlike aluminum abrasives, the ignition point of the

dust is extremely low and the safety is good, And has asianificant whitening

effect on the surface of the workpiece.

Advantage

1 Mainly used for burr removal and cleaning of various aluminum alloy and

zinc die casting products

2 Widely used in automobile, aircraft, shipbuilding, container, machinery

manufacturing, metal casting, metalsurface treatment and other industries, The

product is known as "beautician of meta surfaceZinc shot can be used for

electroplating steel plate and smal parts and other electroplating

industriesstrengthening and deburring of ferrous metal and non-ferrous metal

parts, polishing of non-ferrous metal partsand main surface finishing of parts.

Process

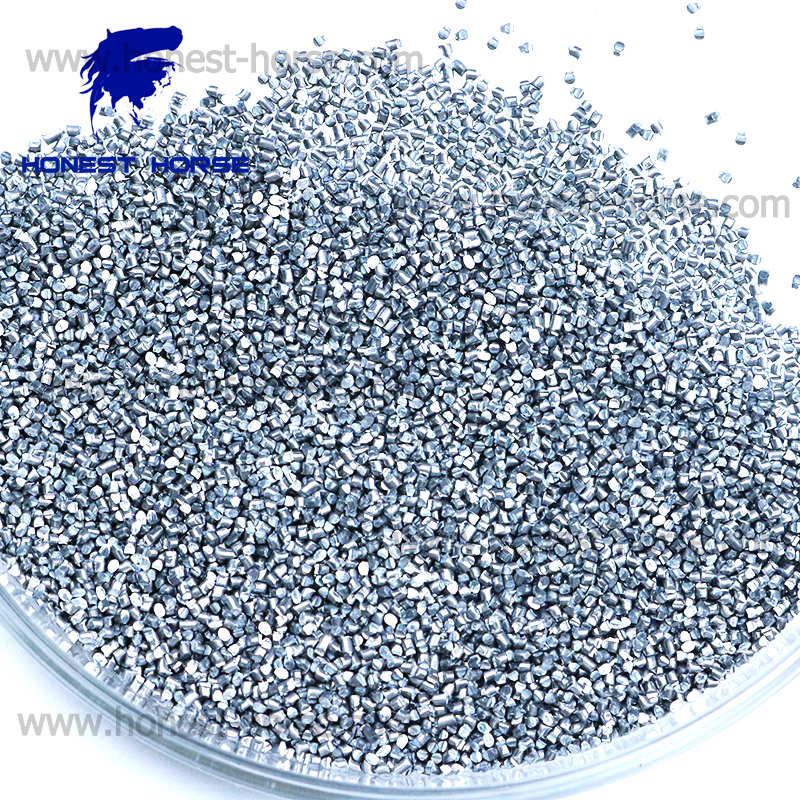

Zinc cut wire shot is produced by advanced process of drawing, cutting and

rounding, the appearance of silver-white. And they are used for deburing and

cleaning on various Aluminum alloy, Zinc die castings. Because their specific

gravity is close to steel and the hardness is low, the deburing can be performed

without wearing the products’ surfaces. Otherwise distinguished from Aluminum

abrasive, the security is nice for much lower kinding point of the dust. And

they are also characterized at obvious whitening on the surfaces of the work

pieces.

Product Detail:

We offer a gualitative range of Zinc Cut Wire Shots, Available at competent

rates, our products reduce wear and tear on blast equipment,These Zinc cut wire

shots are softer than stainless steel cut wire or cast products. Zinc cut wire

shot is available in different sizes. Zinc Cut Wire Shot is produced by cutting

zinc wire into pellets, the length egual to the diameter of the wire. Zinc Cut

Wire is used mainly for sand removal, deburring and deflashing of non ferrous

components. Zinc Cut Wire is also available in a conditioned form which is used

as a longer lasting alternative to cast zinc shot.

|

Product |

Grade |

Chemical composition (%) |

Density |

Hardness |

||||

|

Zn |

Fe |

Al |

Cu |

Co |

||||

|

Zinc cut wire shot - G3 Conditioned |

0#Zn |

99.99% |

0.004% |

0.003% |

0.001% |

0.003% |

7.1g/cm³ |

45-60HV

|

|

Zinc cut wire shot - As Cut |

0#Zn |

99.99% |

0.004% |

0.003% |

0.001% |

0.003% |

35-55HV |

|

|

Name |

Zinc Cut shot |

|

Chemical Composition |

Zn≥99% |

|

Microhardness |

45~50HV |

|

Tensile Strength |

90~120Mpa |

|

Owen life |

6000 times |

|

Mettallographical Stucture |

Deformation alpha |

|

Size |

0.6-2.5mm |

|

Density |

7.1g/cm3 |

|

Packing Density |

4.1 g/cm3 |

|

Sizes Available (Sizes of zinc cut wire shots are as per customer need or as conditioned) |

0.6 mm to 2.00 mm |

|

Minimum Order Quantity |

25 Kilogram |

|

Material |

Zinc |

|

Packaging Type |

PP Bag |

|

Shapes |

Zinc As Cut Zinc ConditionedCCW (G1) DCCW (G2) SCCW (G3) |

|

Al |

0.003% |

|

Cu |

0.001% |

|

CO |

0.002% |

|

Zn |

99.99% |

|

Fe |

0.004% |

|

Hardness |

Cylindrical – 35-55 HVSpherical – 45-60 HV |

|

Density |

7.1g/cm3 |

|

Bulk Density |

4200 Kg/m3 |

Please Fill In The Following Form To Contact Us

2005-2022 © All Rights Reserved.HONEST HORSE (CHINA) HOLDING LIMITED

English

English Spanish

Spanish Arabic

Arabic