How Can Enterprises Optimize Procurement and Usage Strategies?

I. Optimizing Procurement Strategies to Lower Costs

Diversify Supplier Channels – Avoid reliance on a single supplier by introducing competition or establishing long-term agreements with multiple suppliers to secure better pricing and stable supply.

Bulk Purchasing and Negotiation – Collaborate with industry partners for centralized procurement to enhance bargaining power, or stock up during off-seasons to reduce costs.

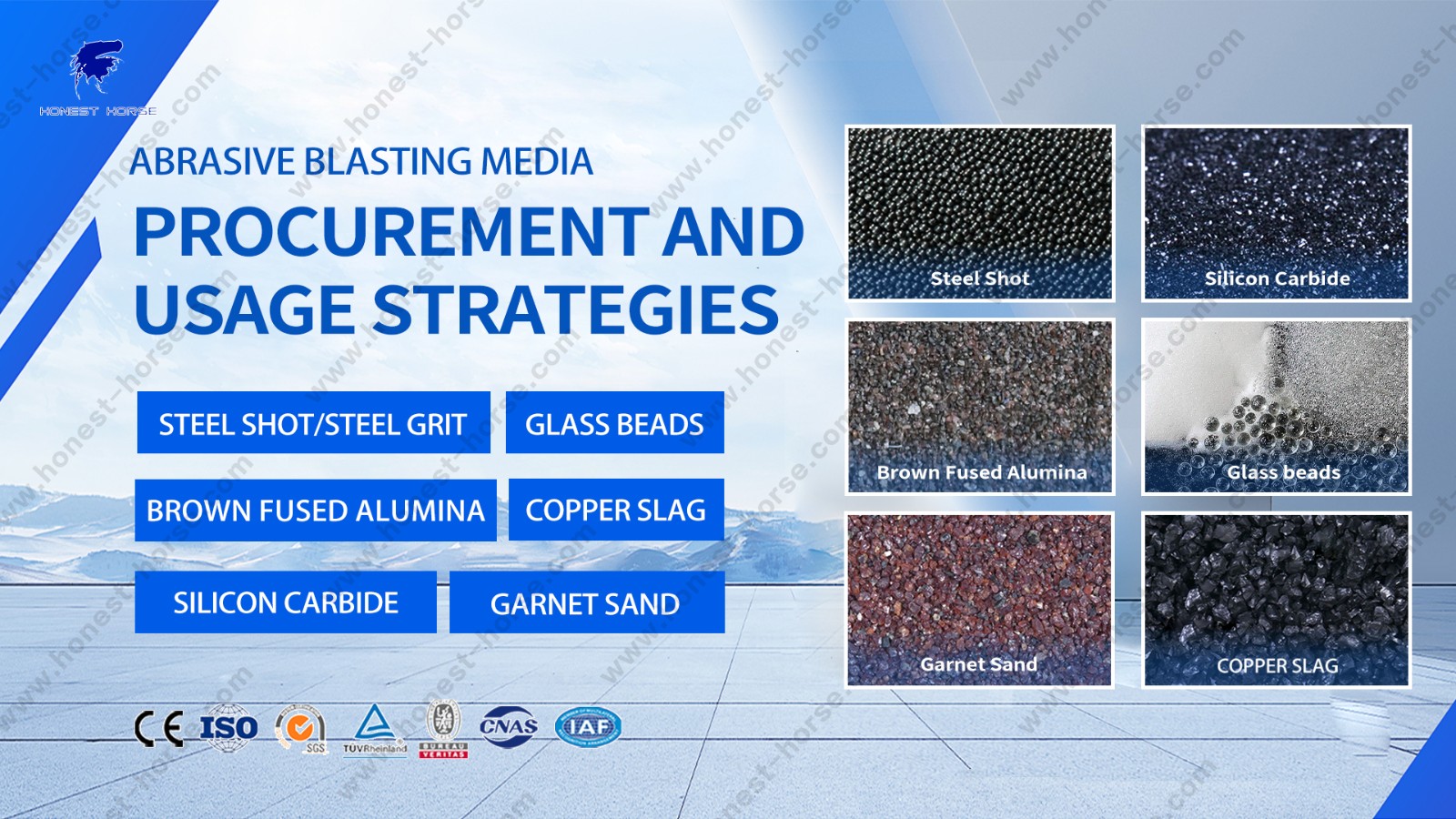

Evaluate Alternative Materials – Without compromising quality, explore cost-effective substitutes such as copper slag or glass beads to reduce dependence on high-priced abrasives.

2. Improving Usage Efficiency to Minimize Waste

Equipment Upgrades and Process Optimization – Adopt high-efficiency blasting equipment (e.g., recyclable blasting systems) to reduce media loss, and optimize parameters (e.g., pressure, angle) to maximize utilization.

Recycling Technologies – Implement abrasive recovery systems to sieve and clean used media, extending its service life.

Employee Training and Standardized Management – Enhance operator skills to prevent excessive blasting or improper handling, and establish consumption monitoring systems for regular usage analysis.

Faced with rising abrasive costs, enterprises must balance procurement optimization with usage efficiency. By improving supply chain management, upgrading technology, and refining operational processes, they can achieve cost reduction and efficiency gains. In the long run, adopting sustainable and circular production models will not only cut expenses but also enhance competitiveness.For more suggestions on abrasive usage and cost control, please feel free to discuss with our company!

2005-2022 © All Rights Reserved.HONEST HORSE (CHINA) HOLDING LIMITED

English

English Spanish

Spanish Arabic

Arabic