Black Corundum (Al2O3) is a crystal shape of aluminum oxide, or is also known

as iron bauxite cuz it contains traces of iron as well. It is melted at high

temperature in the arc furnace, which is further smelted and then cooled in

order to get the metal (α-Al2O3) from its ore. Which is environmentally

friendly, alternative wear resistant material. On the flip side, it contains the

impurities of silicon oxide and titanium oxide.

According to the various levels of alumina content, black alumina abrasives can

be divided into two types. The higher the aluminum content, the higher the

hardness of black alumina and the stronger its grinding performance.

Features:

1. Black corundum has good self-sharpening qualities, low heat during

grinding process, and good workpiece smoothness. Befitting for polishing the

bottom surface of parts before electroplating, aluminum products, and stainless

steel, as well as optical glass polishing, wood processing, etc. t

2. Due to its good hydrophilicity, it can be used in the manufacturing of

sandpaper, Emery cloth, and resin abrasives. Furthermore, it comes in handy in

the manufacturing of grinding paste and polishing powder.

3. 3. Black corundum is not appropriate for manufacturing ceramic abrasives due

to its high iron content.

Key differences between various types.

Aluminum content is one of the vital differences between white, brown and black

corundums.

White corundum contains more than 99% aluminum.

Black corundum contains 45-75% aluminum.

Brown corundum contains 75-94% aluminum.

2) Hardness.

White corundum has the highest hardness.

Brown corundum has average hardness.

The hardness of black corundum considered to be minimal among these three types

of corundum.

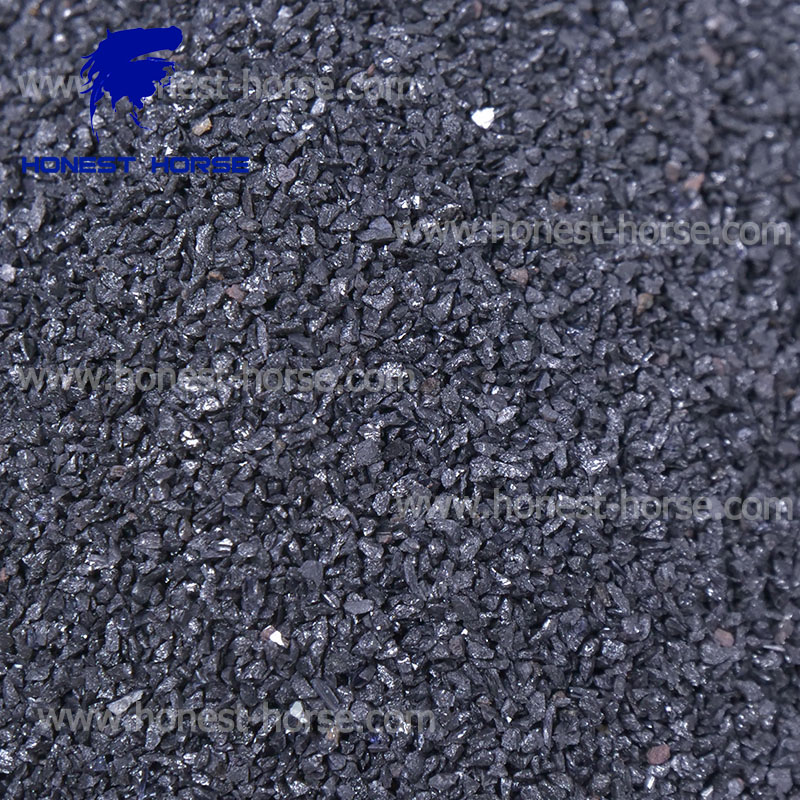

3) Different colors.

Black corundum has metallic black color.

Brown corundum is brownish red.

White corundum is transparent and has white color.

4) Different Uses.

White one is used for the manufacturing of advanced refractory materials and

precision polishing and grinding.

Brown corundum is used for sandblasting and rust removal.

Black corundum is cost effective and mainly used for rough polishing and

non-slippery and wear resistant floor aggregates.

|

Black Aluminum Oxide |

|||||||||||

| Grade | Leading indicator | Density | maximum service temperature | Hardness(mohs) | Melting point | Application | Size | Crystal shape | |||

| AI2O3 | Fe2O3 | SiO2 | TiO2 | 3.5g/cm3 | 1850 ℃ | 9 | 2050 ℃ | Polishing, grinding, sanding, sandblasting | 12--320mesh | Trigonal crystal system | |

| A | ≥ 62 | 6-12 | ≤ 25 | 2-4 | |||||||

| B | ≥ 80 | 4-8 | ≤ 10 | 2-4 | |||||||

Please Fill In The Following Form To Contact Us

2005-2022 © All Rights Reserved.HONEST HORSE (CHINA) HOLDING LIMITED

English

English Spanish

Spanish Arabic

Arabic