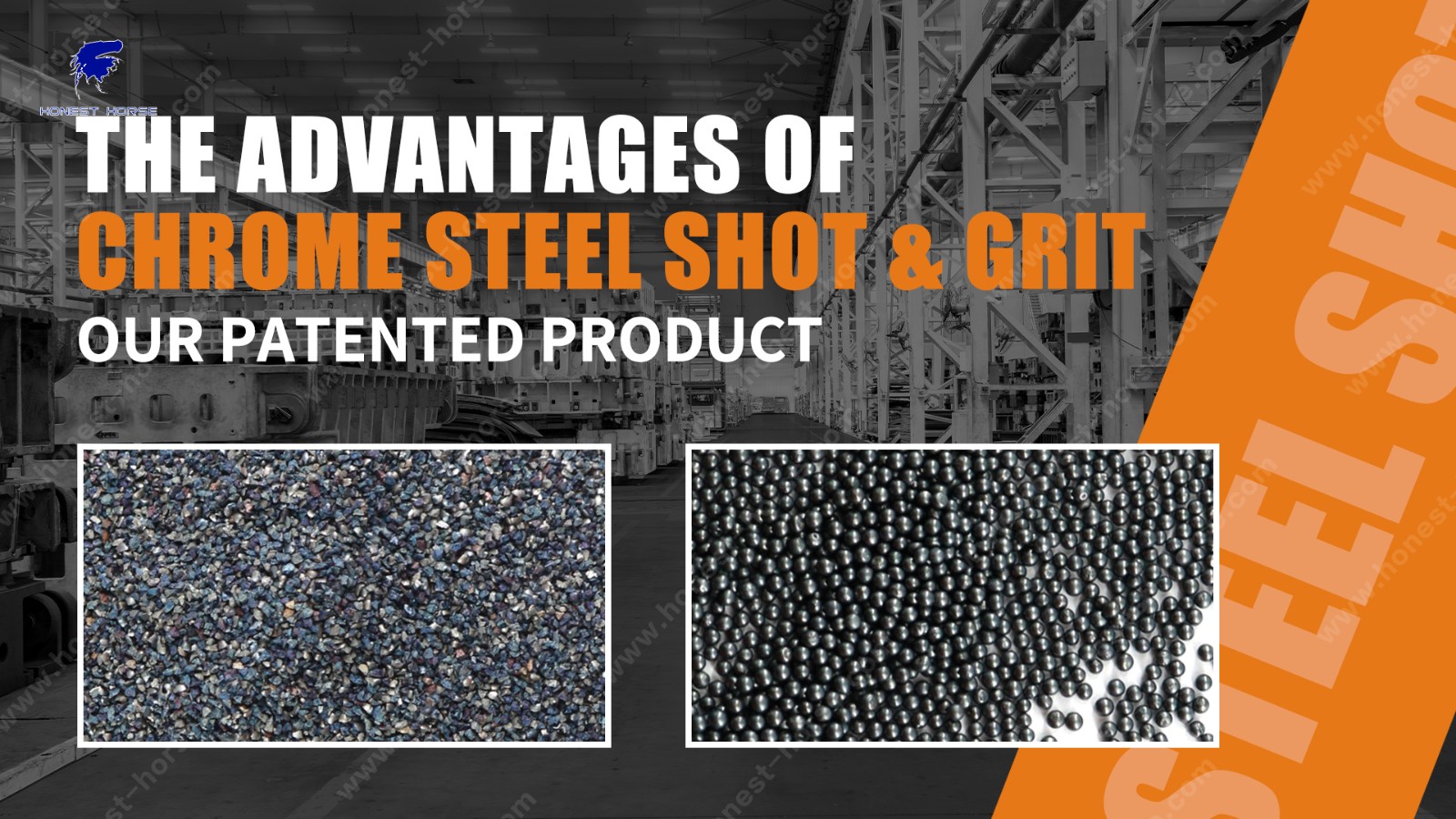

The Advantages of Chrome Steel Shot &Grit-Our Patented Product

By adding certain Chrome element in the production, it makes the steel good tenacity, crush and fatigue resistance, so the difference is Chrome steel shot&grit fatigue life is even up to 3000 times, more than 400 lifetime than standard steel shot&grit without Chrome.

During the production of chrome steel shot &grit, elements such as ferrochrome and ferromanganese are added to increase toughness and wear resistance, reduce deformity rate, and thus increase the overall service life and make it more durable.

1.Application

(1)Surface Cleaning and Rust Removal

High-Efficiency Cleaning: Chrome shot&grit has a high hardness (typically HRC 42-51 and Hrc 54-60), effectively removing scale, rust, old coatings, or weld residue from metal surfaces.

(2) Surface Roughness Control

Uniform Roughening: By adjusting the particle size (typically 0.2-1.5mm) and blasting pressure, a uniform surface roughness (Ra value) can be achieved, enhancing coating adhesion.

(3) Surface Strengthening (Shot Peening)

Residual Compressive Stress: The impact of chrome shot creates a compressive stress layer on the metal surface, improving fatigue resistance and stress corrosion resistance (particularly suitable for aerospace and automotive parts).

(4) Special Applications

Precision Workpiece Treatment: Chrome shot with uniform particle size can be used for surface treatment of precision parts to avoid excessive damage.

2.Advantages

We are the only factory in China , producing Chrome alloy steel shot & grit with latest technology. The Cr steel shot & grit are more cost-effective than double quenching process.Our chrome steel shot & grit products can compete with top brands internationally .

2005-2022 © All Rights Reserved.HONEST HORSE (CHINA) HOLDING LIMITED

English

English Spanish

Spanish Arabic

Arabic