About:

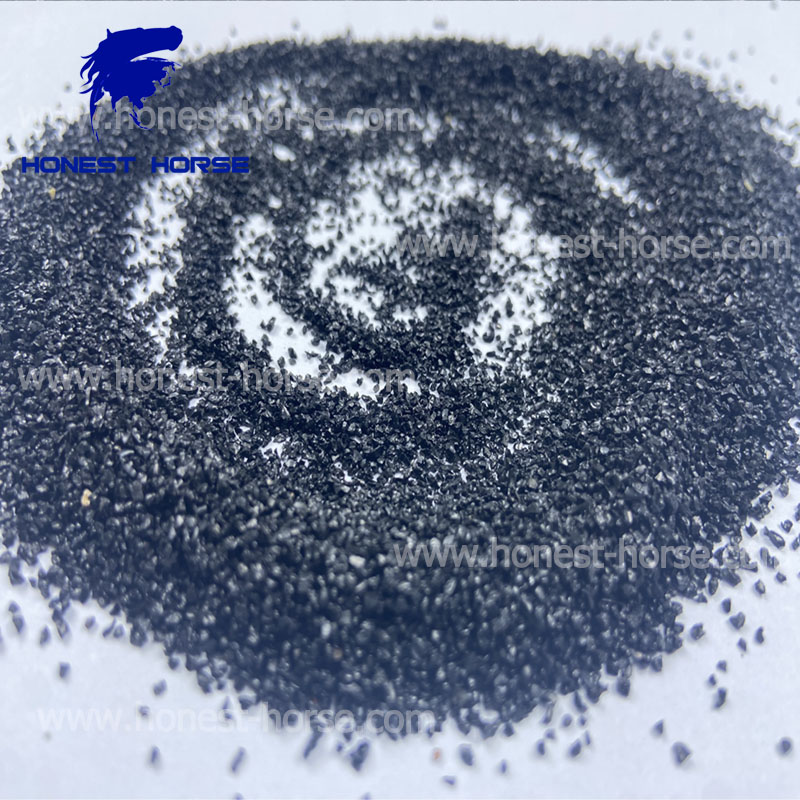

Copper ore, also known as copper slag sand or copper furnace sand, is the slag

produced after copper ore is smelted and extracted, also known as molten slag.

The slag is processed by crushing and screening according to different uses and

needs, and the specifications are expressed by the mesh number or the size of

the particles. Copper ore has high hardness, shape with diamond, low content of

chloride ions, little dust during sandblasting, no environmental pollution,

improve the working conditions of sandblasting workers, rust removal effect is

better than other rust removal sand, because it can be reused, economic benefits

are also very considerable, 10 years, the repair plant, shipyard and large steel

structure projects are using copper ore as rust removal.

When quick and effective spray painting is needed, copper slag is the ideal

choice. Depending on the grade, it produces heavy to moderate etching and leaves

the surface coated with primer and paint. Copper slag is a consumable silica

free substitute for quartz sand.

Advantages:

Silica free (less than 0.1%)

Fast and effective surface cleaning

Very low dust

Meets the requirements of SSPC-AB1 and MIL-A-22262B (SH)

Clean surface finish

Surface profile from 2.0 to 5.0

Efficient sandblasting and use less grit

application

Rust, paint and oxide removal

Bridge removal and maintenance

Barge and ship blasting

Military vehicles and boats stripped

Water tower stripping

Surface treatment of new metals

High pressure sprinkler system

| Product name | Leading indicator | Density | Moisture | PH | Hardness(mohs) | Bulk density(g/cm3) | Application | Size | |||||

| Copper Slag / Iron Silicate | TFe | AI2O3 | SiO2 | MgO | Cu | CaO | 3.85g/cm3 | 0.18% | 7 | 7 | 3.98g/cm3 | Refractory materials, fine casting |

6-10mshe ; 10-20mesh ; 20-40mesh ; |

| 46.1% | 16.54% | 25.34% | 1.45% | 0.87% | 8.11% | ||||||||

Please Fill In The Following Form To Contact Us

2005-2022 © All Rights Reserved.HONEST HORSE (CHINA) HOLDING LIMITED

English

English Spanish

Spanish Arabic

Arabic