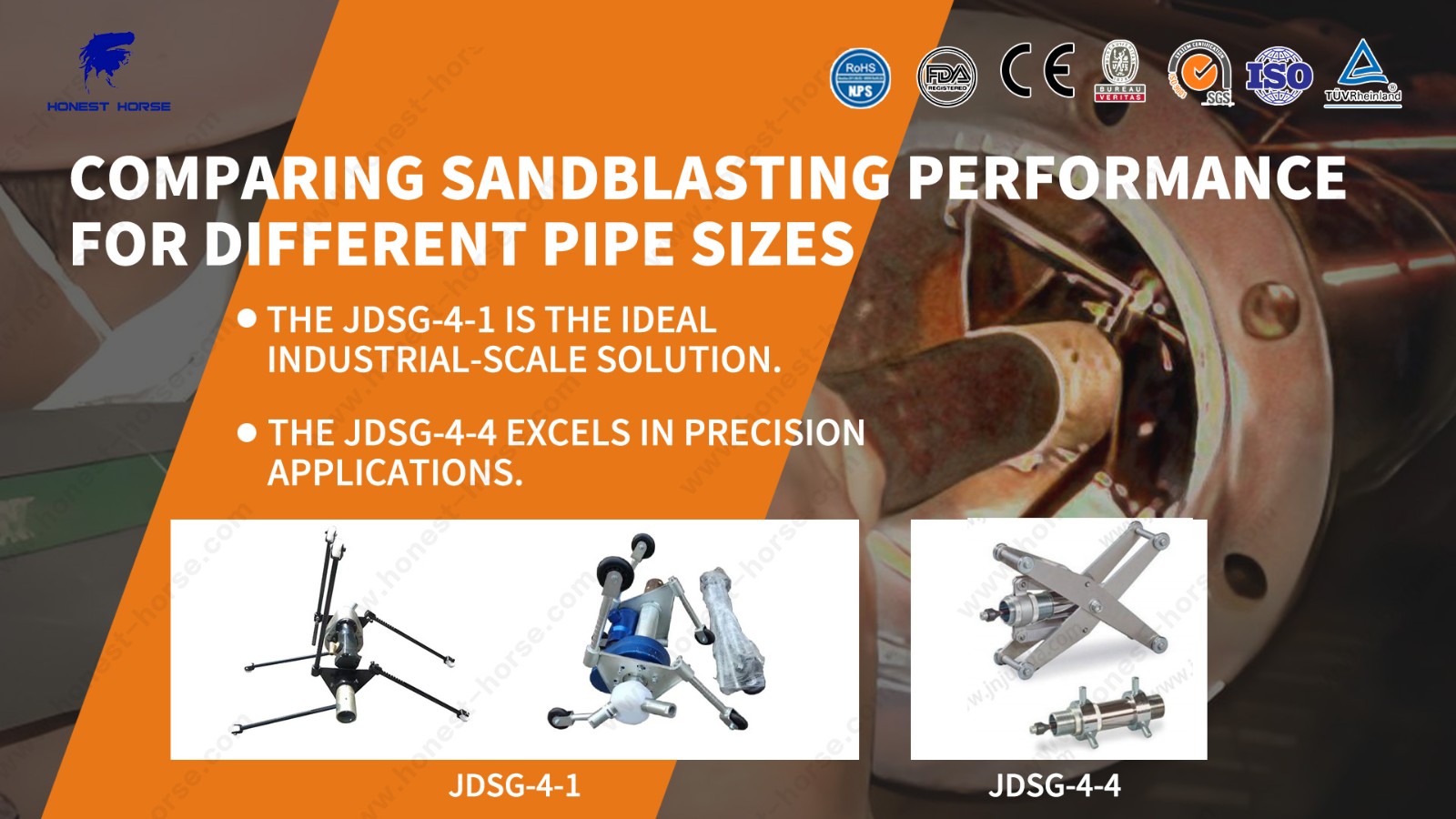

Comparing Sandblasting Performance for Different Pipe Sizes

For large-diameter pipelines (300-900mm), the JDSG-4-1 is the ideal industrial-scale solution. Its robust design features two sandblasting heads on a single gun, powered by a pneumatic motor that drives a full 360-degree rotation. This ensures complete, uniform coverage of the wider interior surface. Furthermore, its adjustable roller bracket allows for quick adaptation to different pipe sizes within its range, ensuring stable operation and consistent, high-efficiency cleaning in larger spaces.

In contrast, for smaller pipes (60-250mm), the JDSG-4-4 excels in precision applications. It is compact, lightweight, and specifically engineered for confined spaces. Its anti-sand design at the loose sand head prevents clogging, while maintaining effective 360-degree sandblasting capability. The inclusion of two brackets (large and small) enhances stability within narrower pipes, contributing to its remarkably fast cleaning speed.

In summary, while the JDSG-4-1 delivers powerful, adaptable performance for large-scale industrial piping, the JDSG-4-4 offers agility and precision for smaller diameters. Together, they ensure optimal surface preparation—from heavy-duty cleaning to fast, detailed work—across a comprehensive spectrum of pipeline maintenance needs.

2005-2022 © All Rights Reserved.HONEST HORSE (CHINA) HOLDING LIMITED

English

English Spanish

Spanish Arabic

Arabic