![]() Product Description

Product Description

Size: Dia20- 150mm

Material: C45, 60Mn, 65Mn, 40Cr 42 Crmo,B2,B3, B6

Hardness: C45:48-55HRC, 60Mn:57-61HRC,

B2:60-64HRC, B3:62-65HRC, B6:62-65HRC

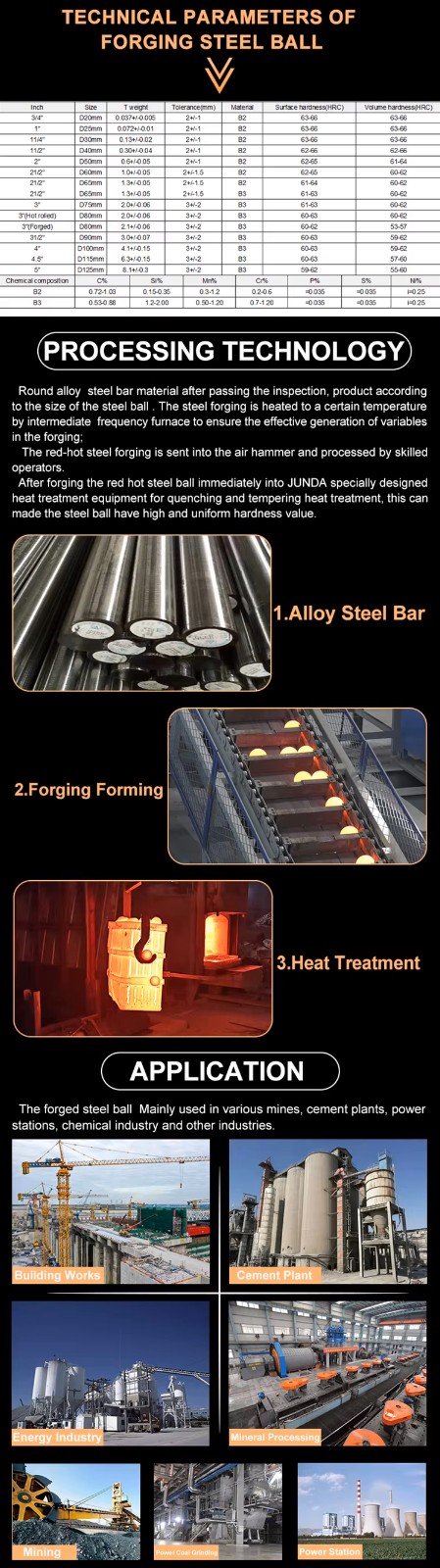

The manufacturing process of steel balls

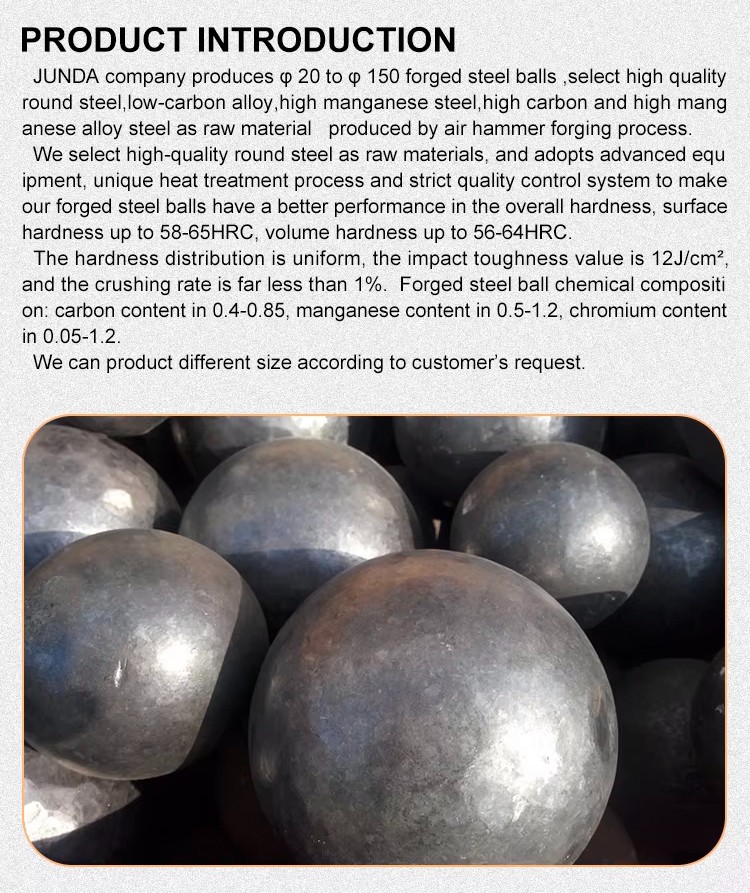

JUNDA company produces φ20 to φ 150 forged steel balls ,select high quality round steel,low-carbon alloy ,high manganese steel,high carbon and high manganese alloy steel as raw material produced by air hammer forging process.

We select high-quality round steel as raw materials, and adopts advanced equipment, unique heat treatment process and strict quality control system to make our forged steel balls have a better performance in the overall hardness, surface hardness up to 58-65HRC, volume hardness up to 56-64HRC.

The hardness distribution is uniform, the impact toughness value is 12J/cm2,and the crushing rate is far less than 1%. Forged steel ball chemical composition: carbon content in 0.4-0.85, manganese content in 0.5-1.2, chromium content in 0.05-1 2.

We can product different size according to customer's request.

| Container Bag | Steel Drum | |

| Ball size | Net Weight | |

| 20-30mm | 930-1000KGS | |

| Net weight 1000kgs for all size balls | 40-60mm | 900-930KGS |

| 70-90mm | 830-880KGS | |

| 100mm and above | 830-850KGS | |

Bag:73x60cm,1.5KG.0.252CBM

Drum:60x90cm,15-20KG,0.25CBM

Pallet Single:60x60x9cm,4-6KG: Double:120x60x10cm,12-14KG

Which certifications has our company obtained?

Which certifications has our company obtained?

Our operations and products are backed by key international certifications, including ISO 9001 for quality management, CE for the European market, and KOC for South Korea. These credentials are not just badges of compliance but essential enablers of our global reach, supporting our exports to a network of over 100 countries and reinforcing our clients' trust in our professional standards.

Please Fill In The Following Form To Contact Us

2005-2022 © All Rights Reserved.HONEST HORSE (CHINA) HOLDING LIMITED

English

English Spanish

Spanish Arabic

Arabic