HONEST HORSE forged steel ball, relied on advanced equipment and production

technology, our forged steel ball has the advantages of high hardness, good wear

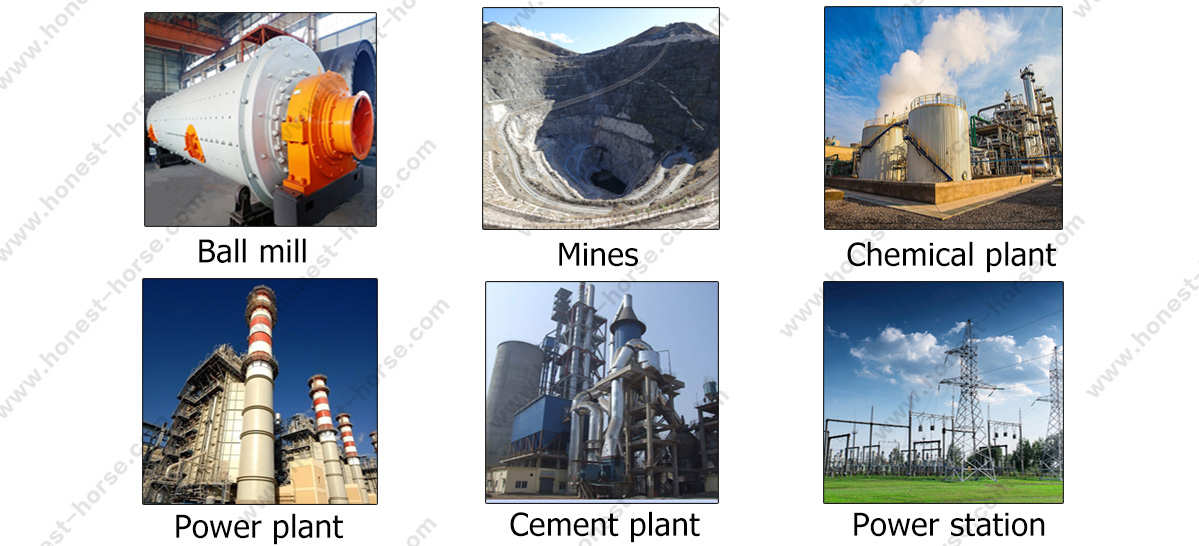

resistance, no fracture, uniform wear and so on. The forged steel ball Mainly

used in various mines, cement plants, power stations, chemical industry and

other industries. In order to ensure the excellent performance of grinding ball,

we have established a perfect quality testing system, advanced quality control

and testing equipment. We have also obtained ISO 9001:2008International quality

system certification. Hoping for your cooperation.

HONEST HORSE company produces φ 20 to φ 150 forged steel balls ,we select high

quality round steel,low-carbon alloy,high manganese steel,high carbon and high

manganese alloy steel as raw material produced by air hammer forging process. We

select high-quality round steel as raw materials, and adopt advanced equipment,

unique heat treatment process and strict quality control system to make sure the

better performance of forged steel balls in the overall hardness. the surface

hardness is up to 58-65HRC, volume hardness is up to 56-64HRC. The hardness

distribution is uniform, the impact toughness value is 12J/cm², and the crushing

rate is far less than 1%. Forged steel ball chemical composition: carbon content

is 0.4-0.85, manganese content is 0.5-1.2, chromium content is 0.05-1.2, We can

produce different size according to customer’s request. We have also obtained

ISO 9001:2008International quality system certification.

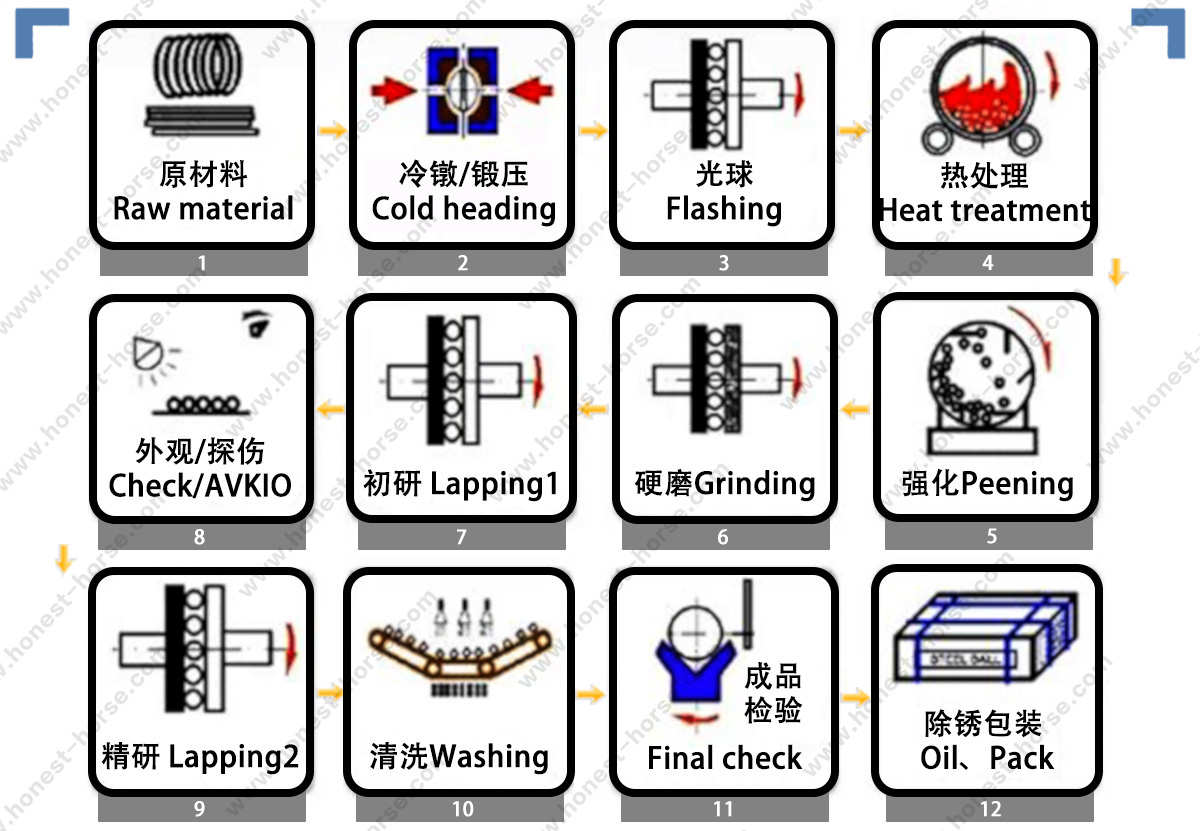

Producing process

After checking and testing the round alloy steel bar material,the production

can be started according to the size of the steel ball . The steel forging is

heated to a certain temperature by intermediating with frequency furnace to

ensure the effective generation of variables in the forging; The red-hot steel

forging is sent into the air hammer and processed by skilled operators. After

forging the red hot steel ball immediately into HONEST HORSE specially designed

heat treatment equipment for quenching and tempering heat treatment, the high

and uniform hardness value of the steel ball can be ensured.

Product features:

1.High impact toughness

2.Compact organizationr>

3.High wear resistance

4.Low breakage rate

5.Uniform hardness

6.No deformation

Packing And Transportation

Packing And Transportation

|

Container Bag |

Steel Drum |

|

|

Net weight 1000kgs for all size balls |

Ball size |

Net Weight |

|

20-30mm |

930-1000KGS |

|

|

40-60mm |

900-930KGS |

|

|

70-90mm |

830-880KGS |

|

|

100mm and above |

830-850KGS |

|

|

Bag:73×60cm, 1.5KG, 0.252CBM Drum:60×90cm, 15-20KG, 0.25CBM Pallet Single:60×60×9cm, 4-6KG:Double:120×60×10cm, 12-14KG |

||

|

Technical parameters of forging steel ball |

||||||||||||

| Inch | Size | T weight | Tolerance(mm) | Material | Surface hardness(HRC) | Volume hardness(HRC) | ||||||

| 3/4" | D20mm | 0.037+/-0.005 | 2+/-1 | B2 | 63-66 | 63-66 | ||||||

| 1" | D25mm | 0.072+/-0.01 | 2+/-1 | B2 | 63-66 | 63-66 | ||||||

| 11/4" | D30mm | 0.13+/-0.02 | 2+/-1 | B2 | 63-66 | 63-66 | ||||||

| 11/2" | D40mm | 0.30+/-0.04 | 2+/-1 | B2 | 62-66 | 62-66 | ||||||

| 2" | D50mm | 0.6+/-0.05 | 2+/-1 | B2 | 62-65 | 61-64 | ||||||

| 21/2" | D60mm | 1.0+/-0.05 | 2+/-1.5 | B2 | 62-65 | 60-62 | ||||||

| 21/2" | D65mm | 1.3+/-0.05 | 2+/-1.5 | B2 | 61-64 | 60-62 | ||||||

| 21/2" | D65mm | 1.3+/-0.05 | 2+/-1.5 | B3 | 61-63 | 60-62 | ||||||

| 3" | D75mm | 2.0+/-0.06 | 3+/-2 | B3 | 61-63 | 60-62 | ||||||

| 3"(Hot rolled) | D80mm | 2.0+/-0.06 | 3+/-2 | B3 | 60-63 | 60-62 | ||||||

| 3"(Forged) | D80mm | 2.1+/-0.06 | 3+/-2 | B3 | 60-62 | 53-57 | ||||||

| 31/2" | D90mm | 3.0+/-0.07 | 3+/-2 | B3 | 60-63 | 59-62 | ||||||

| 4" | D100mm | 4.1+/-0.15 | 3+/-2 | B3 | 60-63 | 59-62 | ||||||

| 4.5" | D115mm | 6.3+/-0.15 | 3+/-2 | B3 | 60-63 | 57-60 | ||||||

| 5" | D125mm | 8.1+/-0.3 | 3+/-2 | B3 | 59-62 | 55-60 | ||||||

| Chemical composition | C% | Si% | Mn% | Cr% | P% | S% | Ni% | |||||

| B2 | 0.72-1.03 | 0.15-0.35 | 0.3-1.2 | 0.2-0.6 | ≤0.035 | ≤0.035 | i≤0.25 | |||||

| B3 | 0.53-0.88 | 1.2-2.00 | 0.50-1.20 | 0.7-1.20 | ≤0.035 | ≤0.035 | i≤0.25 | |||||

Please Fill In The Following Form To Contact Us

2005-2022 © All Rights Reserved.HONEST HORSE (CHINA) HOLDING LIMITED

English

English Spanish

Spanish Arabic

Arabic