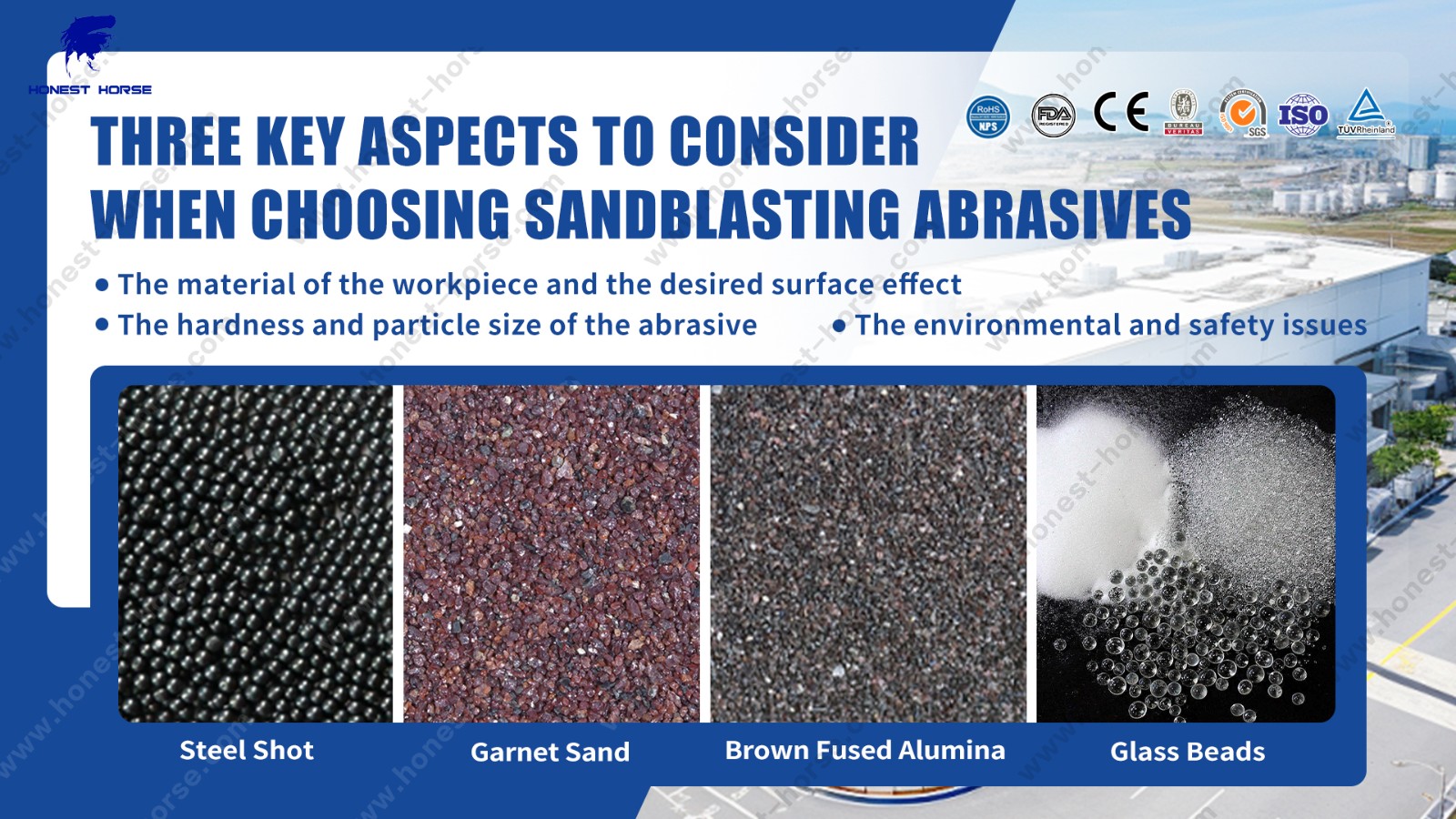

Three key aspects to consider when choosing sandblasting abrasives

Surface Treatment Requirements

1.Workpiece Material: Different materials (such as metal, plastic, glass) require different types of abrasives. Hard abrasives are suitable for cleaning and treating hard surfaces, while softer abrasives are better for more delicate or sensitive materials.

2.Desired Effect: Select abrasives based on the specific target effect.

3.Roughening: Large particle size abrasives can achieve a rougher surface texture.

4.Fine Cleaning or Polishing: Small particle size or finer abrasives can produce a smoother finish.

Physical Properties of Abrasives

1.Hardness: The hardness of the abrasive must be higher than that of the workpiece material to effectively remove surface dirt or old paint.

2.Particle Size: The particle size of the abrasive affects the fineness of the sandblasting effect. Large particle size abrasives have a stronger impact and are suitable for removing stubborn dirt, while small particle size abrasives are better for more delicate work to achieve a smoother surface finish.

Safety and Environmental Considerations

1.Dust and Health Hazards: Some abrasives (such as quartz) can produce fine dust, posing a risk to the respiratory health of operators. Therefore, strict protective measures must be taken, such as wearing protective gear and maintaining a clean working environment.

2.Environmental Impact: Certain abrasives may contain harmful substances and need to comply with environmental regulations during handling and disposal. Choosing environmentally friendly abrasives can reduce potential harm to the environment.

2005-2022 © All Rights Reserved.HONEST HORSE (CHINA) HOLDING LIMITED

English

English Spanish

Spanish Arabic

Arabic