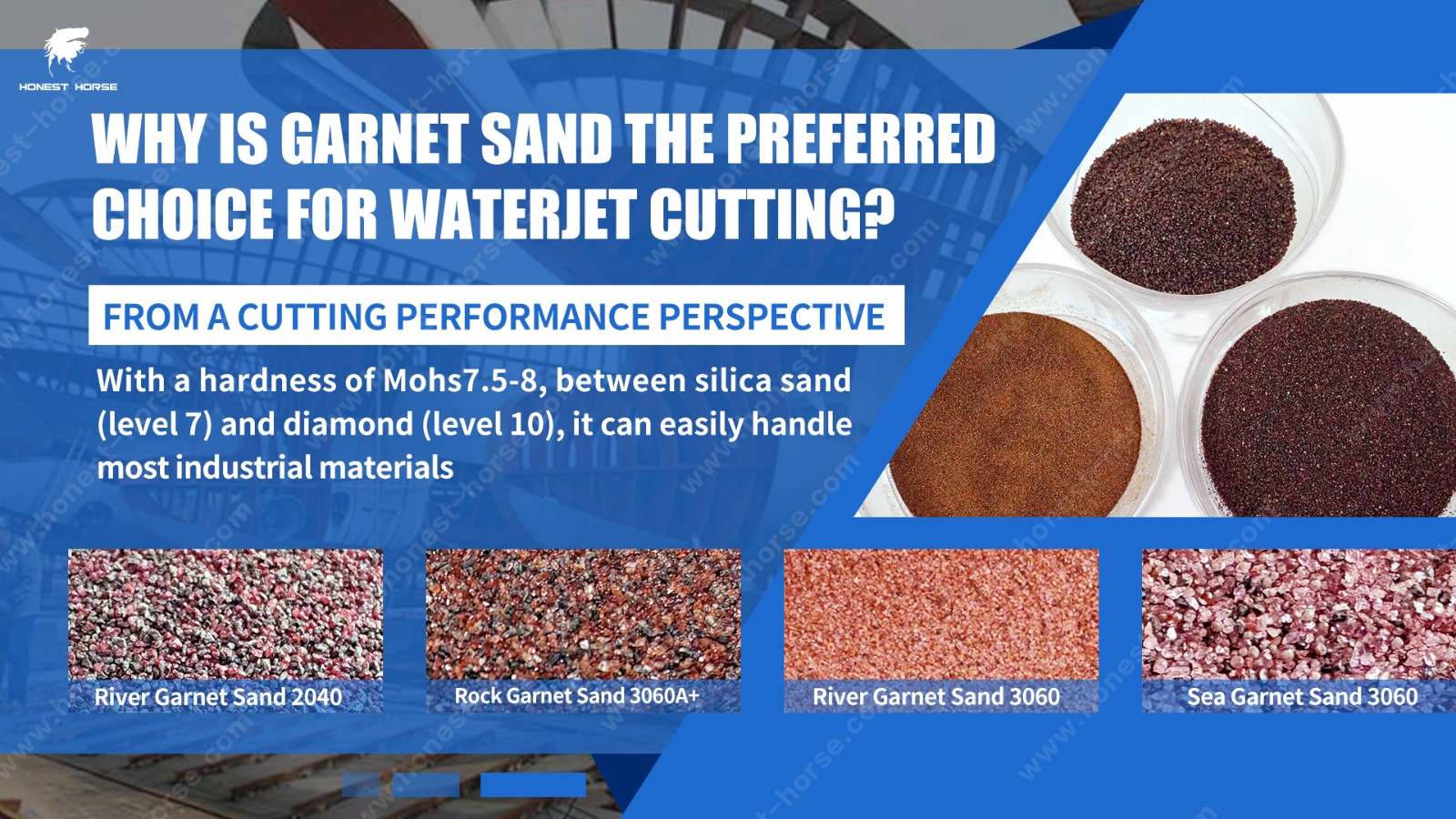

Why is garnet sand the preferred choice for waterjet cutting

From a cutting performance perspective, garnet's hardness and cutting structure provide a natural advantage. With a hardness of Mohs7.5-8, between silica sand (level 7) and diamond (level 10), it can easily handle most industrial materials such as metals, stone, and glass—for example, it can penetrate 20mm thick stainless steel without repeated impacts. Unlike diamond, its high hardness doesn't rapidly wear down expensive cutting nozzles, significantly extending nozzle life and reducing equipment maintenance frequency. Furthermore, natural garnet crystals fracture into sharp-edged polyhedral structures, forming numerous "natural cutting edges." Compared to the rounded edges of silica sand, it can more efficiently "crush" materials during cutting, resulting in significantly higher cutting efficiency than ordinary silica sand, making it particularly suitable for batch processing.

From the cost perspective, garnet's cost-effectiveness is irreplaceable. As a natural mineral abrasive, It’s price is only a fraction of diamond abrasive, extremely lower initial procurement costs. More importantly, garnet particles have moderate toughness, and some undisturbed particles after cutting can be recycled and reused through grading and screening, further reducing the abrasive consumption cost per batch of cutting, making it more economical for the long-term production of small and medium-sized enterprises.

Furthermore, the physical properties of garnet are well-suited to the requirements of waterjet cutting. Its moderate density allows it to suspend evenly in high-pressure water, preventing cutting head clogging caused by particle settling. Its chemical stability ensures it will not react chemically with metals, stone, or other materials during cutting, preventing contamination of the workpiece surface, making it particularly suitable for cutting precision parts requiring high surface cleanliness.

Therefore, considering the above performance, cost, and adaptability, garnet is the optimal choice for waterjet cutting abrasive.

If your cutting operations have specific material requirements (such as thick steel plates or fragile glass) or precision requirements, please feel free to contact us. Our professional technical team will provide you with expert technical support and recommendations.

2005-2022 © All Rights Reserved.HONEST HORSE (CHINA) HOLDING LIMITED

English

English Spanish

Spanish Arabic

Arabic