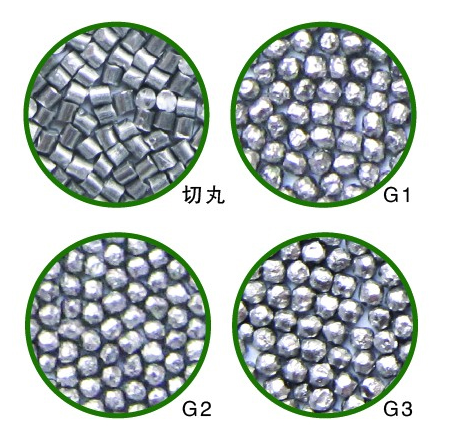

Advantages and applications of wire cut shot

Wire cut shot is widely used in the casting profession. It is mainly made of steel wire cut into pellets, after special processing. Its service life is longer than ordinary cast steel shot, and there is no porosity and loose. It is used by most manufacturers of stainless steel parts and aluminum castings. So, what are the advantages of steel wire pill? Next, let's find out.1, steel wire shot can improve the cleaning quality, because the particle is not broken, the relative impact force is large, the workpiece effect is good after cleaning, high quality.

2. Reduce dust pollution and labor force.

3. Huge economic benefits. The pill has the advantages of good endurance, high strength and unbroken.

4, steel wire shot to reduce blade and impeller wear. From the appearance of the pill, the hardness is low at the beginning of use (HRC40 or so), gradually becomes round after several collisions, and the hardness is higher after plastic deformation (HRC50 or more). After impact crushing (HRC55 or so), the iron ball will cause great damage to the blade and impeller, and the steel wire cut pellets will be more and more round, the wear of the blade and impeller is very small.

Steel wire shot is widely used in casting, forging, machinery, metallurgy, heat treatment, steel structure, grid structure, containers, ships, repair, Bridges, mines, and other fields of sand cleaning, rust removal, strengthening, forming, stress elimination and all kinds of profile appearance cleaning and coating, roughness before electroplating (hair) pretreatment, stone cutting, magnetic shot casting, as heavy concrete and blast furnace resistance Additives of fire materials to increase its wear resistance, high temperature resistance, anti-erosion, electrostatic shielding, anti-radiation, oil filter tank, counterweight and so on.

The advantages of uniform particle size, strong resistance, high reuse rate are widely praised and welcomed by users, and enjoy a high reputation in the same profession in China.

2005-2022 © All Rights Reserved.HONEST HORSE (CHINA) HOLDING LIMITED

English

English Spanish

Spanish Arabic

Arabic