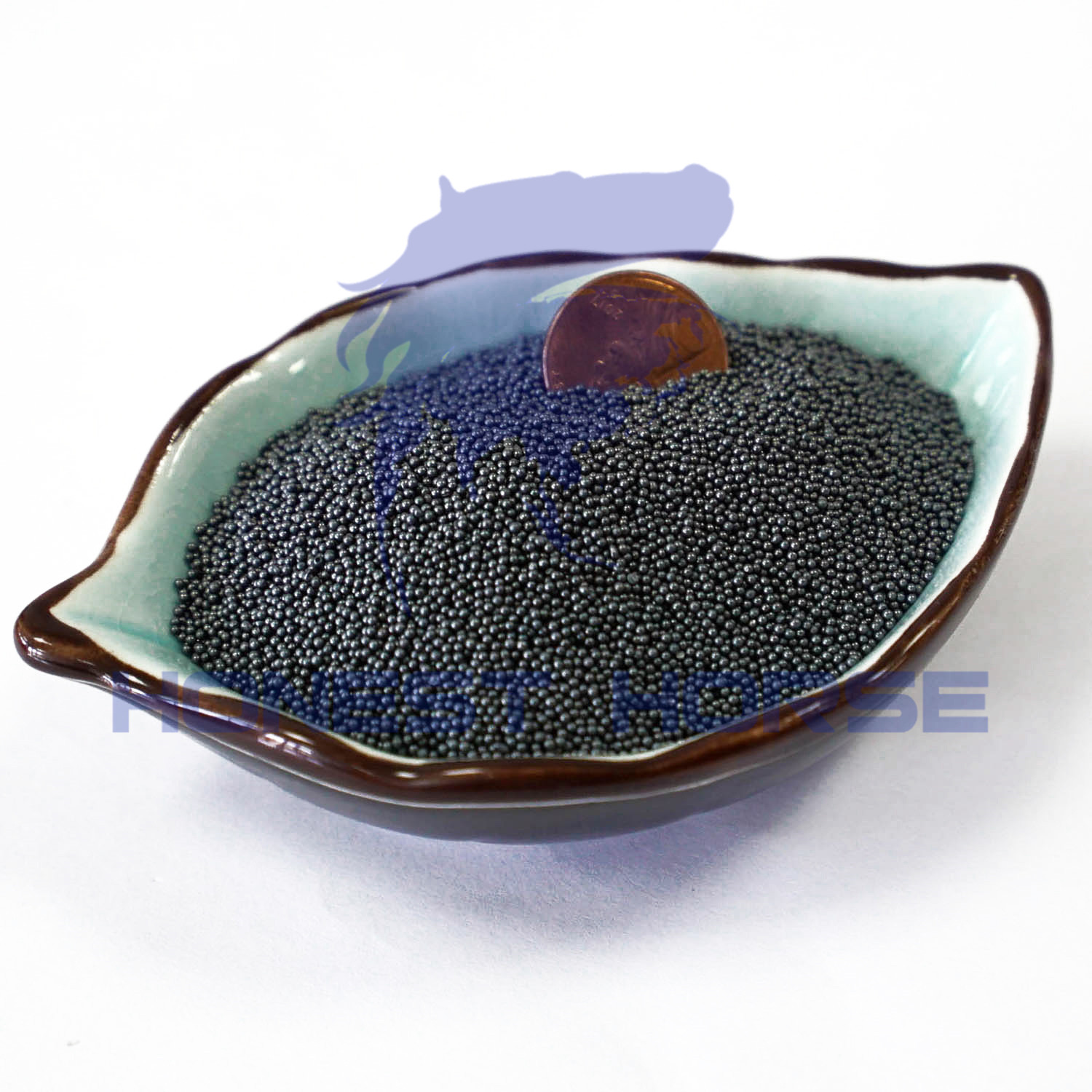

Experiment on the relationship between wear resistance and tempering temperature of steel shot

The wear resistance of steel shot tempered at different temperatures gradually decreases with the increase of tempering temperature.The wear resistance of steel shots under high-stress abrasive wear was tested with a small jaw crusher.

The size of the jaw plate was 22 x137> <191mm. S390 steel shot is used as the fixed plate, and low carbon steel (0.19% C) is used as the moving plate. Under the same conditions, the stone ore with a grain size of 4o ~ 5omm is expected.

The wear resistance of the fixed plate is measured by the wear ratio. The wear ratio is the weight loss of the moving plate divided by the wear loss of the fixed plate. S390 steel pellets have different microstructures under different heat treatment states, and their wear ratios are different. The experiments show that the S390 steel pellets are air-cooled after austenitizing at 950 ° C, and the structure is fine flaky pearlite; after austenitizing, they are oil-quenched and tempered at 650 ° C, and they are fine spherical carbides distributed on the ferrite matrix. After austenitizing, it is oil-quenched and tempered at 205 ° C. It is lath-shaped martensite.

2005-2019 © All Rights Reserved.HONEST HORSE (CHINA) HOLDING LIMITED

English

English Spanish

Spanish Arabic

Arabic