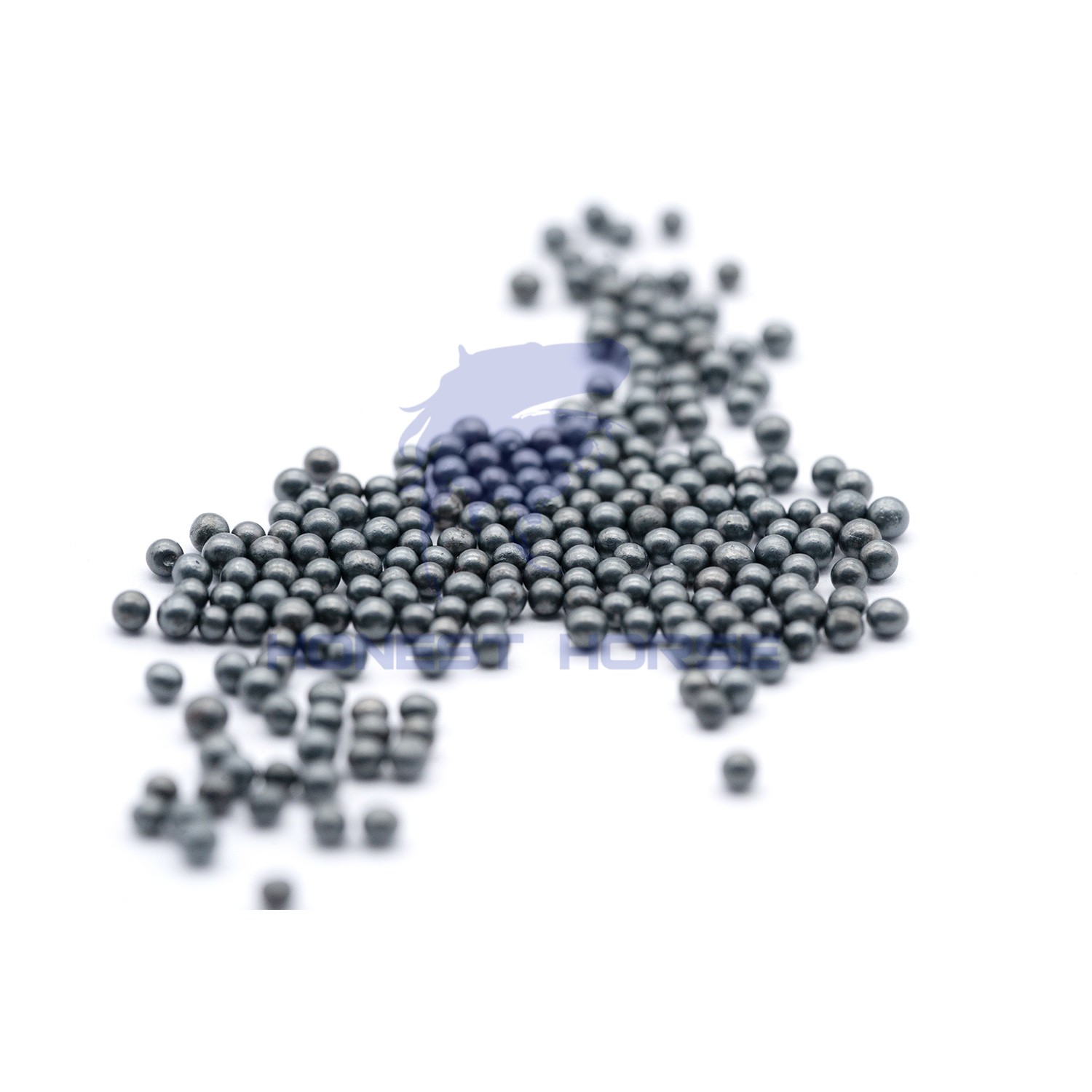

The different of Low carbon steel shot and high carbon steel shot

The low carbon steel shot is bainite structure and don’t have cracks, the consumption is lower 20% than high carbon steel shot during the use process.

Low carbon steel shot has longer life and more durable than high carbon steel shot.

The surface cracks generated by the shot peening operation of high-carbon materials are prolonged in the subsequent heat treatment. This situation does not occur in low-carbon steel shots because they have different structures.

The metallographic structure of the low carbon steel shot after the atomization process is a bainite structure, which is relatively hard and durable.

After being atomized, the high-carbon steel pellets enter the water and the steel pellets have very high hardness and cracks on the surface. The steel shot is transformed into tempered martensite after quenching and tempering heat treatment, and surface cracks increase along with this process.

2005-2019 © All Rights Reserved.HONEST HORSE (CHINA) HOLDING LIMITED

English

English Spanish

Spanish Arabic

Arabic