The selection of stainless steel shot is directly proportional to work efficiency

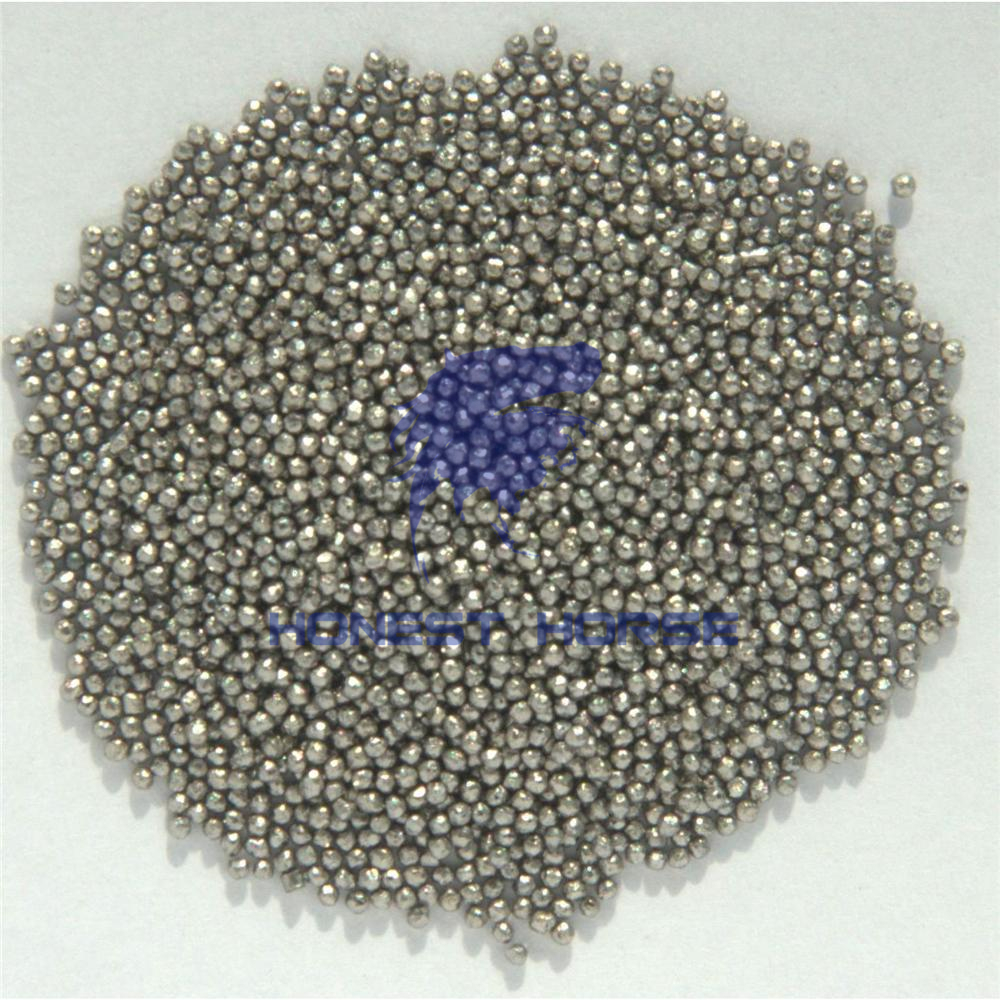

The selection of stainless steel shot is directly proportional to work efficiency. The correct selection of stainless steel shot is the key to improve work efficiency. The following problems should be paid attention to in the correct selection of steel shot; Determining steel shot mainly depends on the type of workpiece you want. Aluminum shot or stainless steel shot is generally used for non-ferrous metals; Steel shot is selected for ordinary steel weldments, castings and steels; The larger the steel shot diameter, the higher the surface roughness after cleaning, but the work efficiency is also very high; The cleaning efficiency of steel grit or steel wire cutting shot with irregular shape is higher than that of spherical shot, but the surface roughness is also higher; The projectile with high cleaning efficiency will wear the equipment quickly; Only the use time is counted, but compared with the production efficiency, the wear is not fast; The hardness of steel shot is directly proportional to the cleaning speed, but inversely proportional to the service life.

2005-2019 © All Rights Reserved.HONEST HORSE (CHINA) HOLDING LIMITED

English

English Spanish

Spanish Arabic

Arabic