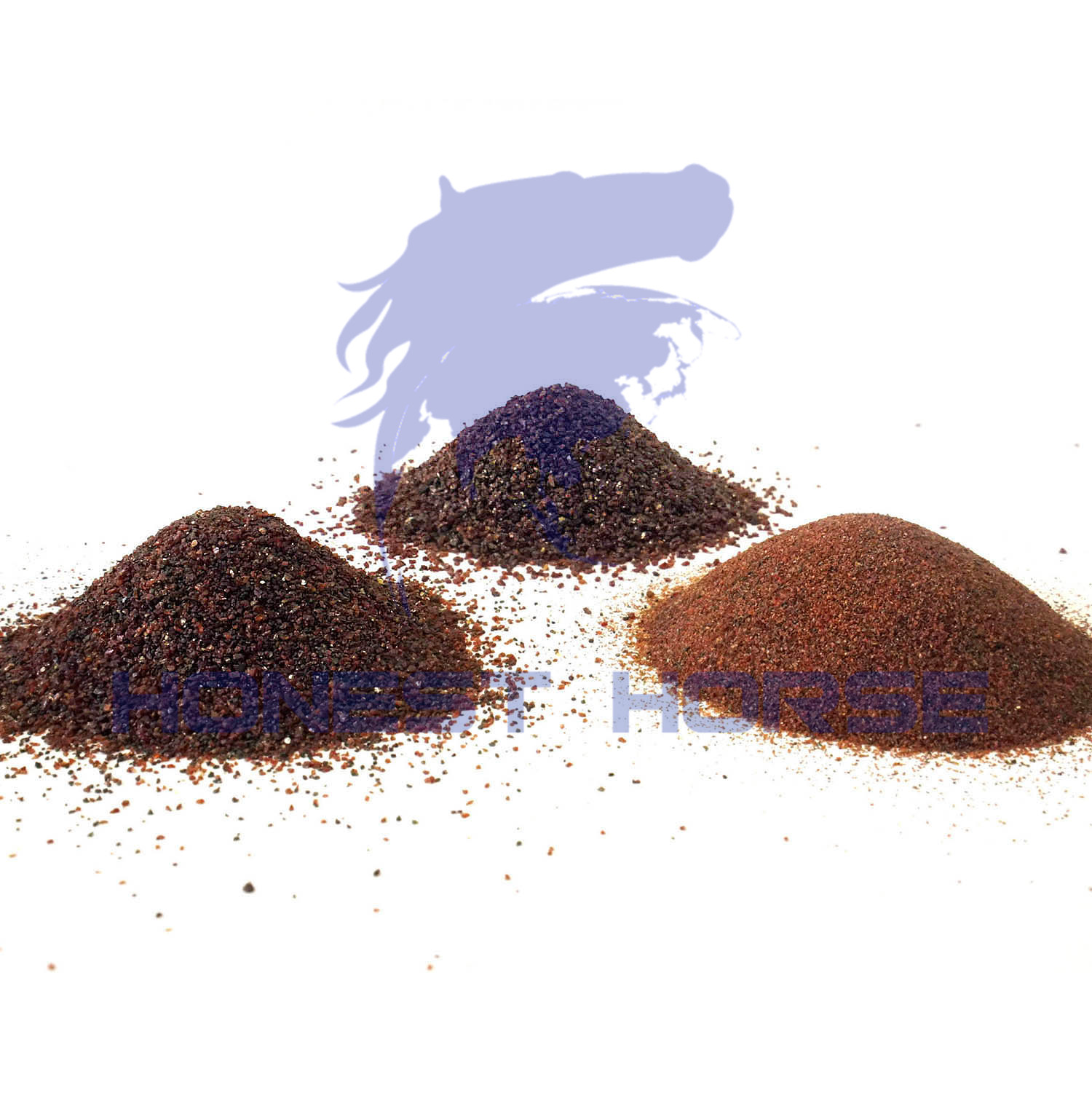

Natural Garnet sand

Natural emery is also called garnet sand. This is because of the conditions under which it is produced.It is a silicate mineral. The garnet raw material can be divided into several grades after simple processing, and the grinding material made by screening and grading methods is very hard, about 7-8 degrees Mohs.

Generally, it is brown powdery particles. After grinding, it can be used as grinding powder, can be used to make polishing paper, and can also be used to make friction surfaces of grinding wheels and vermiculite.

There is a long history of production and use. In ancient China, there were historical examples of using emery to grind crystal glass and various jade. In the 1840s, it was exported to Toyo. It is divided into three categories: coarse, medium and detailed. All kinds of mesh size are uniform, the shape of the particles is uniform, and the edges are called angular crystals. They have sharp edges and high grinding force. For stone industrial grinding marble and other soft materials. Glass industry grinding glass burrs, television picture tubes, optical instruments, lenses, prisms, glass for watches, etc.

Metal blasting, derusting and grinding. Printing industry grinding offset plate, and light industry processing plastic samples, leather, sandpaper and other uses. The grinding force of natural corundum is slightly lower than that of electric furnace white corundum, but its toughness is strong, and it has the characteristics of a shell-shaped section mouth. Its advantages are high smoothness of the grinding parts, few and shallow sand marks. The grinding surface is fine and uniform, which can improve product quality. Natural garnet has short grinding time, high efficiency and low price, which can make up for the short life.

2005-2019 © All Rights Reserved.HONEST HORSE (CHINA) HOLDING LIMITED

English

English Spanish

Spanish Arabic

Arabic