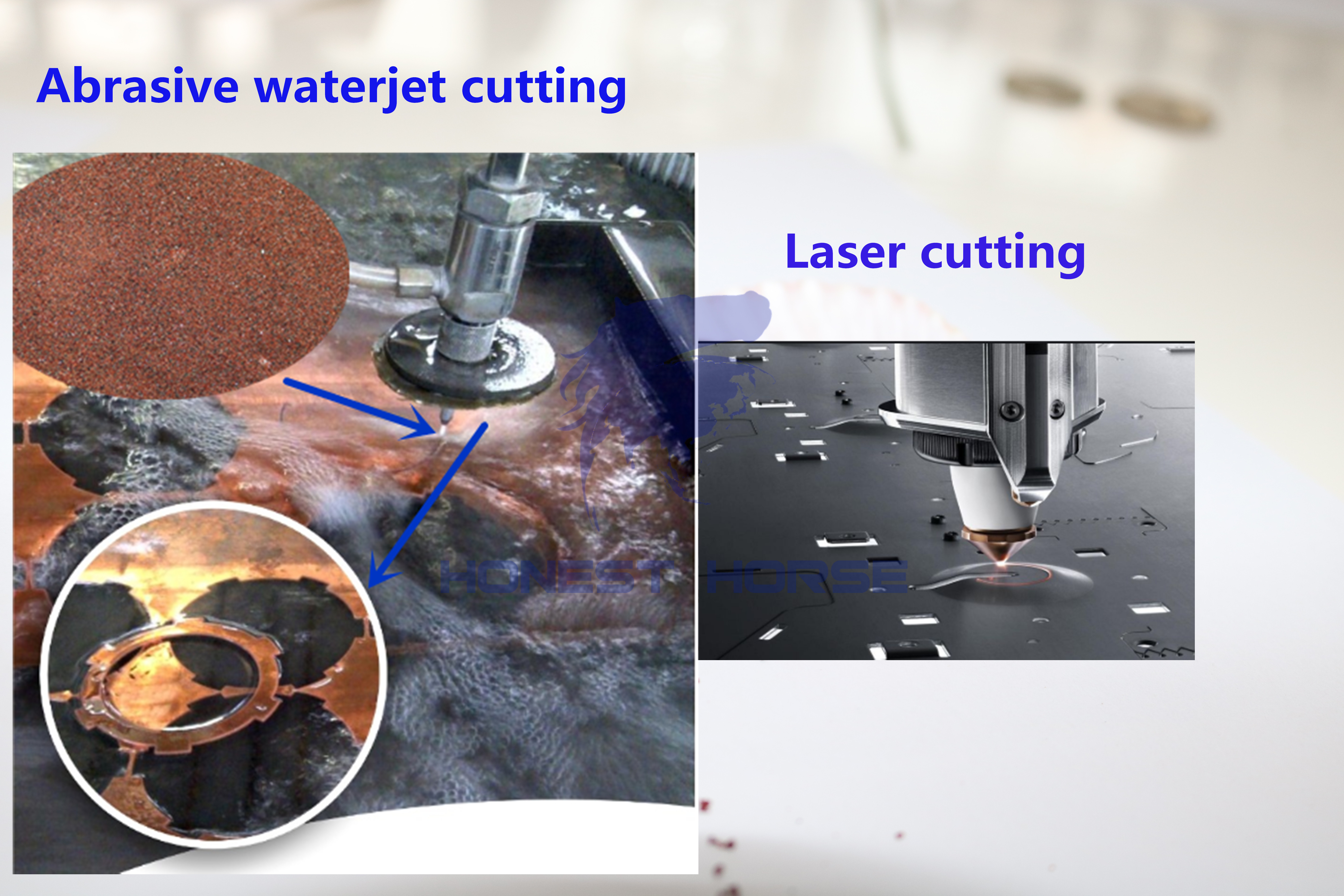

The difference of Waterjet cutting and Laser cutting

Cutting thickness

Cutting by water allows cutting of everything and even a wider thickness than the laser can reach.

The cutting system is carried out through a jet of water at very high pressures, mixed with abrasive sand to achieve cutting work of up to 150 mm. Thickness, in high strength materials. Obtaining finished contours and pieces of great quality, impossible to achieve with traditional tools.

cutting material

The soft materials (wood, plastics, polyurethanes, fabrics, paper, cardboard and others) are cut with a pure water preparation. The hard materials are cut with a mixture of water and an abrasive element that increases the effectiveness and quality of the cut.

We could say that it is a powerful water saw with "nanometric" precision, capable of developing the most complex cuts: curves, angles, pinion teeth, irregular figures and more.

Cutting technologies with laser, it cut by means of heat and can cut only those materials that withstand high temperatures, usually metals.

the laser use gases, on the other hand the water jet is innocuous, it does not contaminate nor has additional costs, it does not subject the material to tensions that can deform it.

The thickness starts at below 1 mm and can reach up to 200 mm, although greater precision is achieved at lower thicknesses. The laser do not reach these thicknesses.

2005-2019 © All Rights Reserved.HONEST HORSE (CHINA) HOLDING LIMITED

English

English Spanish

Spanish Arabic

Arabic